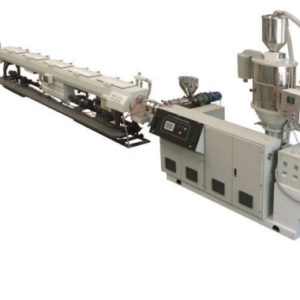

HDPE pipe extrusion line/ HDPE pipe making line

http://www.turui86.com

TURUI had been exported 5 sets 710-1200 mm HDPE pipe extrusion line before, and all clients are still use them well. It adopts Germany technology in the HDPE pipe extrusion line, which has higher production capacity than other plastic pipe manufacturers. TURUI HDPE pipe extrusion line also named HDPE pipe manufacturing machine which is using extrusion process to make HDPE water pipe and PE sewage pipe and it supplied many HDPE pipe machine to HDPE pipe manufacturing plants in China and overseas markets. If you want to know how to make HDPE pipe, please send email to us, our sales team will send your HDPE pipe manufacturing process video for our clients in our factory. TURUI always supply HDPE pipe manufacturing process flow chart to our clients in order to make good understanding for our plastic extrusion machines and guide them how to make HDPE pipe by themselves. https://www.all4plas.com/product/single-shaft-shredder-machine/

Main tech Data:

- Max. output: 1600 kg/h

- Plastic extruder motor power: 410 Kw

- Quantity claw of haul-off: 8 claws

- Plastic extruder: SJ 90/38 and SJ 75/38 single screw extruder

Equipment flow chart List for production large diameter HDPE pipes 710-1200 mm:

| No. | Name | Model | Quantity |

| 1 | Automatic feeding machine | 900 G | 1 set |

| 2 | Hopper dryer | F H 1200 E | 1 set |

| 3 | Single screw extruder (P LC) | SJ 120/38 B 355 KW | 1 set |

| 4 | Meter control system | QM 1000 | 1 set |

| 5 | Single screw extruder | SJ 35/25 | 1 set |

| 6 | Mould | 710-1200 | 1 set |

| 7 | Calibrators | 710-1200 | 1 set |

| 8 | Vacuum calibration tank | Z K-1200 2 M | 1 set |

| 9 | Vacuum calibration tank | Z K-1200 10 M | 1 set |

| 10 | Spray tank | PL 1200 8 M | 3 sets |

| 11 | 10 claw Hauling machine | Q Y-1200 | 1 set |

| 12 | No dust cutting machine | W X Q G-1200 | 1 set |

| 13 | Stacker | FL-1200 | 1 set |

| 14 | Siemens P L C control system | P L C 1200 | 1 set |